Single ply roofing is currently one of the most popular methods of roofing for commercial applications. Most material handling units, including conveyors and carts, were engineered with built-up roofing products in mind – namely tar, felt, gravel, etc. These were (relatively) easy to get to the roof deck using hoists and ladders with

hoisting wheels. Rolls of single ply present a different challenge, as they come in lengths from 6′ up to 12′ and can weigh up to 800lbs, so it’s not as easy as piling rolls on a dolly or wheelbarrow and carting them to where they’re being installed.

Currently, we’ve heard stories of guys having to manually carry these rolls over the deck, which seems back-breaking! We’ve also heard that our

insulation carrier (with or without back wheels) can be used like an oversized dolly (forks are wide enough to balance the rolls). Two other back-saving methods are to place the rolls on a

4-wheel trailer (and use the pins in the pin pockets to prevent roll-off) or to use our newly re-designed

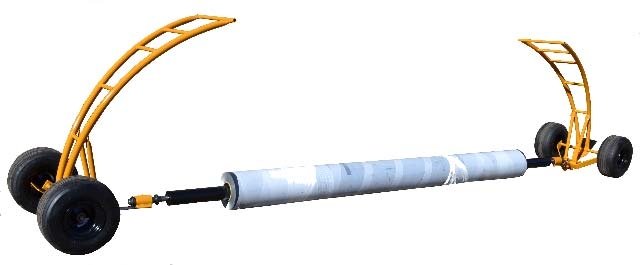

Single-Ply Roll Carrier. All of these carts are offered with pneumatic or our

Non-Flat Lite tires. Note: we recommend the rear-wheels for the insulation carrier. Heavier loads are easier to move on the deck.

Our Single-Ply Roll Carrier is capable of carrying single-ply rolls up to 10 feet wide. It uses a mandrel that separates down into two (2) lightweight sections for easier handling and/or shipping. It breaks down for easy transportation anywhere

(roof or ground); has large tires (18 x 8.50) that make it easy to roll on any deck by any size person; and it has an intermediate handle location to make it very easy to lift up rolls and maneuver them around the roof decks!

Our Single-Ply Roll Carrier is capable of carrying single-ply rolls up to 10 feet wide. It uses a mandrel that separates down into two (2) lightweight sections for easier handling and/or shipping. It breaks down for easy transportation anywhere (roof or ground); has large tires (18 x 8.50) that make it easy to roll on any deck by any size person; and it has an intermediate handle location to make it very easy to lift up rolls and maneuver them around the roof decks!

Our Single-Ply Roll Carrier is capable of carrying single-ply rolls up to 10 feet wide. It uses a mandrel that separates down into two (2) lightweight sections for easier handling and/or shipping. It breaks down for easy transportation anywhere (roof or ground); has large tires (18 x 8.50) that make it easy to roll on any deck by any size person; and it has an intermediate handle location to make it very easy to lift up rolls and maneuver them around the roof decks!